Hyundai Motor Group has confirmed its participation in CES 2026, where the automotive giant will present a comprehensive vision for intelligent automation under the theme “Partnering Human Progress: From Laboratory to Everyday Applications.”

The January 5 keynote presentation at Las Vegas’ Mandalay Bay Convention Center will mark a pivotal moment for the company, as executives outline ambitious plans to integrate sophisticated robotic systems across manufacturing operations and beyond.

Atlas Takes Center Stage

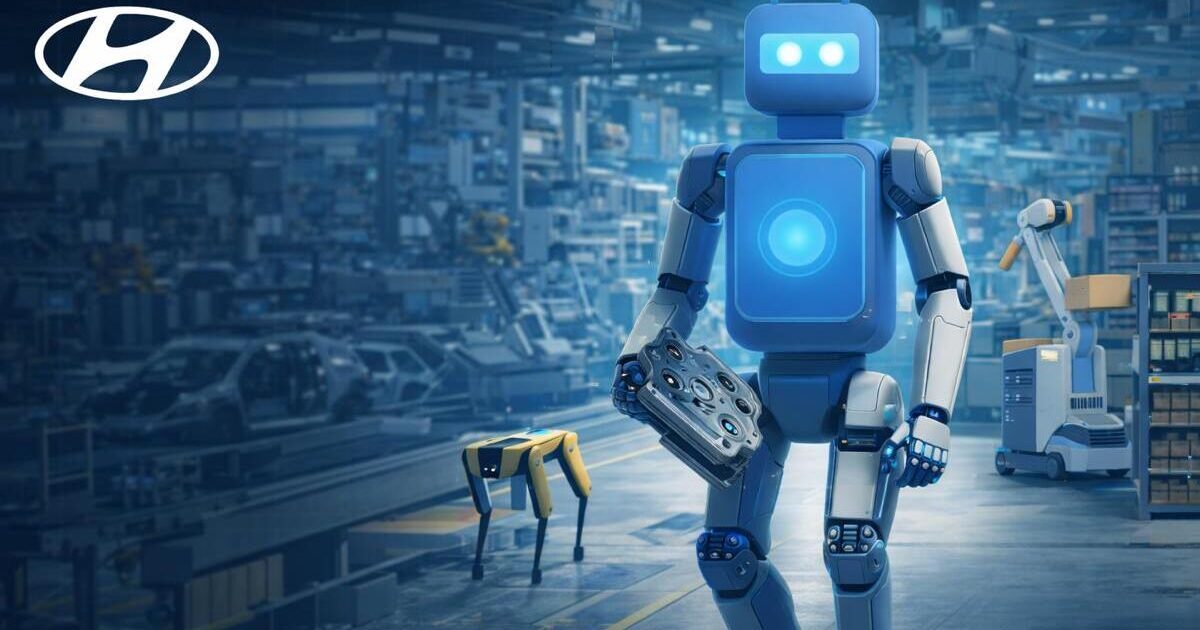

The star attraction will be Atlas, the next-generation humanoid robot developed by Boston Dynamics, Hyundai’s U.S.-based robotics subsidiary. This fully electric platform represents a significant evolution from earlier hydraulic models, offering enhanced strength and remarkable dexterity.

Atlas will begin test operations at Hyundai Motor Group Metaplant America in 2026, autonomously handling basic tasks like sorting and moving auto parts, providing a practical demonstration of how humanoid robots can integrate into existing production environments.

The robot’s capabilities extend far beyond traditional industrial automation. Equipped with machine learning algorithms, Atlas can interpret task sequences and adapt to changing circumstances using real-time sensor feedback. Unlike conventional robotic arms limited to repetitive movements, this platform can perform diverse manufacturing operations with human-like flexibility.

Building an Ecosystem

Hyundai’s robotics ambitions extend well beyond a single product launch. The company plans to deploy additional platforms including Spot, the four-legged inspection robot, and Stretch, designed for logistics operations. These systems will be integrated across Hyundai facilities worldwide as part of a broader transformation initiative.

The strategy centers on what Hyundai calls “software-defined factories” production environments where robotics, data analytics, and digital infrastructure converge to create adaptive manufacturing systems. This approach positions the automotive manufacturer as a comprehensive provider of intelligent production solutions.

During the exhibition, attendees will experience virtual research environments and receive detailed briefings on cutting-edge robotics technologies being developed within Hyundai’s innovation labs.

Strategic Investment in Future Technologies

The robotics initiative complements Hyundai’s substantial investment in electric vehicle technology. The company recently held a ceremony marking construction progress on its Future Mobility Battery Campus in Anseong, South Korea. The $818 million facility, spanning 111,000 square meters, is scheduled for completion by end of 2026 and will serve as a hub for next-generation battery research.

This dual focus on advanced manufacturing and sustainable mobility reflects Hyundai’s broader transformation from traditional automaker to integrated technology provider.

Industry Context and Market Potential

Hyundai’s robotics push comes as the humanoid robot sector experiences rapid growth. Goldman Sachs projects the market will reach $38 billion by 2035, with annual shipments of 1.4 million units. Early movers in this space stand to gain significant competitive advantages as manufacturing enters an era defined by intelligent automation.

The collaboration with Boston Dynamics builds on Hyundai’s 2021 acquisition of a controlling stake in the robotics pioneer for $880 million. That strategic purchase positioned robotics as a core revenue stream alongside the company’s automotive operations.

Executive Chair Chung Euisun previously demonstrated the company’s commitment to this sector at CES 2022, when he appeared onstage with Spot, Boston Dynamics’ quadruped robot. The upcoming presentation promises a more comprehensive vision of how these technologies will reshape industrial operations.

Technical Partnerships Driving Innovation

Recent developments highlight the sophistication of Hyundai’s robotics program. The company has partnered with Toyota Research Institute to develop Large Behavior Models that enable more intuitive robot control. This collaboration focuses on whole-body coordination, allowing humanoid platforms to treat limbs uniformly rather than separating walking and manipulation functions.

Additionally, Hyundai’s Robotics LAB has worked with semiconductor company DEEPX to create next-generation robot intelligence platforms capable of operating independently of cloud services. This capability proves essential for deployment in network-restricted environments such as underground facilities and transportation hubs.

Looking Ahead

As CES 2026 approaches, industry observers are closely watching how Hyundai’s robotics strategy will unfold. The company has demonstrated a pattern of biennial participation in the tech showcase, previously focusing on hydrogen vehicles and software-defined automobiles during CES 2024.

This year’s emphasis on robotics and intelligent automation signals a strategic pivot that could influence the broader manufacturing sector. With advanced hardware, substantial financial backing, and access to real-world deployment environments through its automotive operations, Hyundai appears positioned to play a significant role in the emerging robotics industry.

The January presentation will provide clarity on commercialization timelines, partnership opportunities, and the specific applications where these technologies will first make an impact. For an industry eager to understand how humanoid robots will transition from laboratory demonstrations to productive work, Hyundai’s roadmap may offer important insights into the practical future of intelligent automation